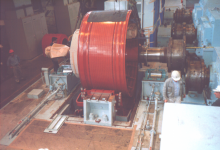

tomorrows small job is to fit an earth lead to the Boutelje extractor.

there is no earth lead from the body to earth, so the whole body can become live posing major health risk.

and yes i tested it with a meter.

the older one got away with it because it connects through the bearing and it has a cast alloy bearing housing.

however the newer one has a plastic bearing housing.

the other connection point is through the little torque reaction plate. but as thats not actually bolted down (it wobbles on a stud) so the connection goes from good to non-existent, especially with a bit of dirt/honey/wax build up on it.

highly recommend fitting an earth lead from the body to the earth leads before someone has a shocking time of it.

there is no earth lead from the body to earth, so the whole body can become live posing major health risk.

and yes i tested it with a meter.

the older one got away with it because it connects through the bearing and it has a cast alloy bearing housing.

however the newer one has a plastic bearing housing.

the other connection point is through the little torque reaction plate. but as thats not actually bolted down (it wobbles on a stud) so the connection goes from good to non-existent, especially with a bit of dirt/honey/wax build up on it.

highly recommend fitting an earth lead from the body to the earth leads before someone has a shocking time of it.