Yes in the UK that would be earth bonded, as would the copper pipes carrying the water !!! Unless it was in an area of earth free bonding, but then everything would be at the same potential.Do you also earth your stainless steel bench top ?

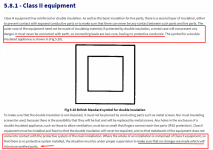

Double insulation protects the user of the appliance from an electrical shock by preventing any possibility of the external casing becoming live (the live wire can not touch the casing even if wires inside become loose), thus eliminating the need for an earth connection. The two layers of insulation are:Interesting take on the rules.

I think from what you have described a tad over reaction

- First insulation: Insulating electrical cable from the internal component of the appliance.

- Second insulation: Insulating internal metal part which could become live from the external casing.

However, according to UK electrical regs you MUST NEVER earth a double insulated appliance.

I have no idea how these translate to NZ regs as I have not done the qualification cross over here.